Engineered to protect

Engineered to protect

All our efforts are aimed at optimizing the performance of your Atlas Copco compressor for the longest lifetime at the lowest operating cost.

The experts in our laboratories are uniquely skilled in specifying lubricant properties for Atlas Copco compressors to operate optimally in a wide range of settings and conditions, during several thousands of hours.

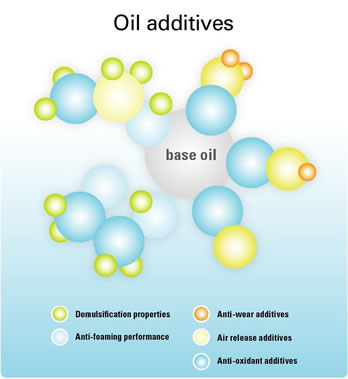

Atlas Copco lubricants are a unique blend of chemical properties, engineered for optimal performance in their dedicated functions.

Lubricants (772kB, Pdf document) - Download

Atlas Copco Fluids for screw compressors

Atlas Copco Fluids for screw compressorsAtlas Copco Roto-Inject Fluid is specially formulated to protect your GA-GX rotary screw compressors and neutralize pollution. It guarantees the longest lifetime, trouble free, with constant performance, at the best operating cost.

Years of experience on thousands of types of Atlas Copco equipment have proven Roto-Inject Fluid to match all lubrication demands in varied conditions. It boasts an extended service interval of up to 4 000 hours for operation in a mild environment. This is critical to achieve the best reliability and reduce the service lifetime cost.

Roto-Inject Fluid (64kB, Pdf document) - Download

Roto-Xtend Duty Fluid

Roto-Xtend Duty FluidWhen your air compressors need to perform at top capacity, only the Atlas Copco lubricant is good enough. That’s why it pays to use Roto-Xtend Duty Fluid. Atlas Copco superior performance long life PAO oil, specifically developed for use in Atlas Copco oil injected screw compressors.

Based on synthetic hydrocarbons and special additives, our

engineered

8 000 hour lubricant has proven its ability to meet all lubrication

demands under widely varying conditions. Roto-Xtend Duty

Fluid increases compressor reliability, reduces lifetime

operating costs and makes your equipment last longer.

Roto-Xtend Duty Fluid (184kB, Pdf document) - Download

Roto-Foodgrade Fluid is a high performance fluid specifically

designed for use in oil injected screw compressors operating

in the food and beverage and packing industry. National and

international regulations specify strict manufacturing standards

regarding contamination risk management in this industry.

Roto-Foodgrade Fluid is a high performance fluid specifically

designed for use in oil injected screw compressors operating

in the food and beverage and packing industry. National and

international regulations specify strict manufacturing standards

regarding contamination risk management in this industry.

Our Roto foodgrade is based on a careful blend of synthetic fluids and additives that meet these stringent requirements , allowing for active Critical Control Points management (in an HACCP system) and providing increased customer confidence in the food products' safety.

Roto-Food Grade Fluid (106kB, Pdf document) - Download

Piston compressors pose extreme demands to lubricants:

the high compression temperature - possibly exceeding 150°C

(300°F) - pressures up to 20 bar, condensation - typically

during low cycle load - and dust contamination in installations

that are not optimally maintained.

Piston compressors pose extreme demands to lubricants:

the high compression temperature - possibly exceeding 150°C

(300°F) - pressures up to 20 bar, condensation - typically

during low cycle load - and dust contamination in installations

that are not optimally maintained.

Traditional lubricants cannot cope with these extreme conditions, resulting in fast oil degradation, overheating and potentially irreversible damage and high repair costs. Therefore, high performing lubricants increase the equipment lifetime. The Atlas Copco Piston Fluid has been developed as a high resistance lubricant, withstanding severe conditions, with a long service interval and superior performance.

Considering the low oil content in piston compressors, often less than 2 liters, the economy of lesser quality oils simply is not worth the risk.

Piston Fluid (56kB, Pdf document) - Download

Roto-Z Lubricants

Roto-Z Lubricants Roto-Z is a high quality lubricant, uniquely tailored to the specific requirements of the Atlas Copco Z-compressors. Its special formulation yields top performance and maximum lifetime of all moving parts. Reliability is safeguarded and equipment availability is maximal.

Roto-Z is cost-effective too: drain intervals are doubled

in comparison

to conventional lubricants.

Roto-Z incorporates the functional benefits of a preservative

mineral

oil, which allows for an extended on-site storage of several

months.

Roto-Z (71kB, Pdf document) - Download

Recip Oil is a unique lubricant, especially created for Atlas

Copco oil-free reciprocating compressors and boosters. The

special blend provides optimum lubrication for high pressure

applications and guarantees top performance and maximum durability

of all moving parts. This improved reliability translates

into maximum equipment uptime.

Recip Oil is a unique lubricant, especially created for Atlas

Copco oil-free reciprocating compressors and boosters. The

special blend provides optimum lubrication for high pressure

applications and guarantees top performance and maximum durability

of all moving parts. This improved reliability translates

into maximum equipment uptime.

Recip Oil (60kB, Pdf document) - Download

Select below to send your request

by email to an appropriate product specialist.

Please include your contact information (name, phone, email,

company, location, etc.) and a full description of your needs.

We will contact y0u shortly.

Equipment Service or Parts